Oldsmobile/GM found a problem with the depressure valve that is built into the throttle body of the intake system. They came out with a dealer alert in June of 1964 and an improved depressure valve version in February of 1965 for an external depressure valve installation kit. All known Jetfire cars were to have the kit installed.

Oldsmobile/GM found a problem with the depressure valve that is built into the throttle body of the intake system. They came out with a dealer alert in June of 1964 and an improved depressure valve version in February of 1965 for an external depressure valve installation kit. All known Jetfire cars were to have the kit installed.

The depressure valve function is to relieve the positive pressure in the Turbo Rocket Fluid tank and fluid metering system/valve when the engine is shut down.

Following is a detailed summary of my investigative work regarding the depressure valve.

Depressurization Valve Operational Details

Positive value……..

-

The afterthought valve is necessary to remove the possibility of filling a cylinder or two with Turbo Rocket Fluid after engine is shut down. It relieves any pressure/vacuum left in the system (including residual pressure left in the fluid tank) when the engine is turned off.

-

The valve will relieve tank pressure after shut down and eliminate the leaking of Turbo Rocket Fluid out the top (through the green felt “filter”, under the hole in the attaching bracket I install on all of my rebuild jobs) of the fluid metering system, between the fuel filter and the carburetor.

Negative value………

-

All valves I have checked and/or taken apart (except one) have failed! I have learned that they had at least two versions of the valve. First version was introduced in mid 1964 and revision 1 introduced in early 1965. By the time the “improved” valve came out, most of the Jetfires were already converted to 4 barrel carbs! However, after some 40+years, the second valve version fails also! The rubber diaphragm material shrinks and pulls out from under the crimped edges. I am not sure which happens first; pressure/vacuum pulling/pushing the diaphragm material out from the crimp seal or the diaphragm material shrinking and pulling away from the crimp seal? Either way, the failed valve left in place on the turbo NOW creates a new set of problems!

Failed valve on turbo……..

I have run my car with a known failed valve and a new rebuilt valve and have observed the following:

-

I have a rough idle that comes from the vacuum leak through the bad valve. It goes away with a good valve.

- I have a “flat spot” or loss of continued power/acceleration at about 4,000 RPM and up. Turbo boost gauge does not indicate any greater boost from 4,000 RPM up. A good valve will allow the engine to rev up to 4,500 or 5,000 RPM with NO hesitation. Turbo boost gauge will “peg out” on the top end of the gauge scale. The power curve for this engine is now the way it should be! I do NOT fully understand why this happens but a good valve STOPS the problem!

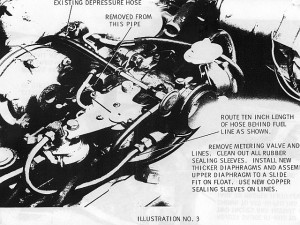

I have almost completed the MAJOR project of reproducing this valve and installation kit. With so few of these valve kits that were dealer installed on the remaining turbo cars from mid 1964 on, I have NOT found enough valves to rebuild and offer for sale. So, I have remanufactured the complete valve, body diaphragm and cover. I have improved the diaphragm attachment method to keep it in place and not allow it to pull away from the crimped cover. Only time will tell if my new valves will hold up for the long haul. I feel this valve IS NECESSARY on all Jetfires. Prevents a major engine failure (hydraulic-ing) when working correct and allows smooth idle and optimum power to be realized when working properly.

You can install the valve yourself. It is mounted on top of the carb. Easy fix………..

I have completed the new manufacture of this depressure valve and installation components and will offer as a stand alone kit for sale. The kit is now available at a price of $250.00, including shipping. You can reach me at: (952) 881-2150.

Happy Jetfires..Jim Noel