Home Page › Forums › Discussion Topics – Ask the Experts › 62 Jetfire engine, trans, & turbo rebuild

- This topic has 69 replies, 8 voices, and was last updated 10 years, 10 months ago by

jensenracing77.

jensenracing77.

-

AuthorPosts

-

February 27, 2012 at 3:00 am #7316

jensenracing77Participant

jensenracing77Participanti had antifreeze under the engine when this car was together. i couldn’t find where it was coming from but thought it must have been the weep hole in the water pump. well, i figured it out. there is a bad spot in the casting on the intake on the bottom side. it is a very small leak but before i cleaned it you could see where it had been leaking. i cleaned the area with glass bead and then put it in my friends ultrasonic cleaner. i took it to two differant weld shops and both told me the same thing. they are telling me that the way this looks it would be best not to weld it. i don’t know anything about welding but i thought this would be no problem for them to do. both places recommended that i use a high temp epoxy called devcon. i have used the stuff before on ATV engines and works great but not sure i want to go that way on this. any recommendations?

Attachments:

You must be logged in to access attached files.

February 27, 2012 at 5:50 am #7317 JimNoelParticipant

JimNoelParticipantBoy, I am with you. I would not use any ‘glue’ to seal up the intake! If you can’t find a welding shop to do the job, I have a great one right here that will ‘get’er done’!

February 27, 2012 at 6:28 am #7318 jensenracing77Participant

jensenracing77Participantmore bad news. i just can’t win. i was inspecting the intake on the inside everywhere i can see and found what looks like a bad crack coming down from the area of the bad casting. i can’t see where it comes through to the outside. my buddy that has the ultrasonic cleaner also has a video scope. i will look at it better with his camera but i am sure it is bad. anyone have a Jetfire intake for sale?

February 28, 2012 at 7:17 am #7320 macf85Participant

macf85ParticipantJust wanted to throw my two cents in here. I agree with Jim that welding is the way to go unless you discover that the cracks you found will force you to find a different intake. I see that your from Indiana. If you’re in Indianapolis surely you can find a good welder capable of working with aluminum. Also, while you have the engine apart you should have your main bearing caps magnafluxed. When I rebuilt my 215 with 4-barrel the machinist found cracks in the #2, #3 and #4 main caps. I got good used replacements from D & D Fabrications at aluminumv8.com. Also, if you’re still looking for pistons I got my new replacements from EGGE Machine at egge.com

February 29, 2012 at 6:46 am #7322 jensenracing77Participant

jensenracing77Participantafter looking at the intake with a video scope i think i had better get another manifold. the crack on the inside looks like it is in line with an intake runner. i can’t see that the crack goes all the way through but i don’t want it to do it after i get a new engine together. i will be calling about one later tonight. to bad i couldn’t have found it before i cleaned it.

February 29, 2012 at 7:15 am #7323 jensenracing77Participant

jensenracing77Participanti done some work on the generator tonight. bead blasted the end caps and painted the pulley and fan with high temp aluminum. the bearings were in great shape. I’m sure i should replace them as cheap as they are but there is nothing wrong with them. i took the seals out and cleaned them. packed new grease in them and put the seals back in. i need to get a new O ring for the back cap where the bearing goes. the brushes look good so i am just repainting it and cleaning it and it is going back together. i would like to recolor the bolts and pulley and all the little parts but i am just painting the bolt heads and parts. this is going to be a driver so i hate to put the money in coloring all the little parts just to have to do it again in a future quality restoration.

Attachments:

You must be logged in to access attached files.

March 2, 2012 at 5:17 am #7324 jensenracing77Participant

jensenracing77Participantfinished my generator. don’t laugh to hard at my paint work on the tag. the tag sure don’t look good. also picked up a couple NOS parts. my transmission mount is bad so i got this one. also picked up this fluid depressurization valve. wonder if it would be any good after close to 50 years sitting in the box? the guy i got the valve from has another one if anyone is interested. how would i test this valve Jim?

Attachments:

You must be logged in to access attached files.

March 4, 2012 at 6:13 am #7325 jensenracing77Participant

jensenracing77Participanti had to solder the tube back on the back of the air breather. i got a little to much on it and it puddled off to the side a little. i got it painted and it isn’t noticeable. also wondering about the float for the fluid tank. did it have a rubber gasket under it or some kind of sealer? what ever it is supposed to be, this one was dried out so much that i couldn’t tell if it was a gasket or sealer. i did find that a rubber gasket we use at work fits perfect. i think i will try to use it. the only problem with it is that it has one hole that is offset just a little. i will have to drill a new hole in the gasket for that one hole. also got other parts painted today. i just sold an NOS Cadillac part on eBay for enough to get my heads done so they will be next.

Attachments:

You must be logged in to access attached files.

March 5, 2012 at 8:49 pm #7330 bcroejuno-comParticipant

bcroejuno-comParticipantjensenracing77 post=300 wrote: finished my generator. don’t laugh to hard at my paint work on the tag. the tag sure don’t look good.

I drove those cars 1/3 million miles, and the generator was a reoccurring problem.

Biggest thing was brushes failing every 40,000 miles. I got a bracket from a 63

and installed an internally regulated alternator from the 70s, bolt in. I got rid of

that clumsy voltage mechanical voltage regulator and a bunch of under hood wiring.

The GEN light still works, rewired directly to the alternator. Saves some weight.

Bruce RoeMarch 10, 2012 at 5:47 am #7337 jensenracing77Participant

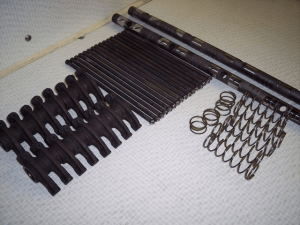

jensenracing77Participantnot much done lately. started working over time at work. i painted more parts and cleaned and reassembled the rocker assemblies but that is about all. i did get the heads sent to D&D.

Attachments:

You must be logged in to access attached files.

-

AuthorPosts

- You must be logged in to reply to this topic.